Factory making China Hard Candy Formed Plant Production Line Candy Equipment for Sale

We always work as a tangible team to ensure that we can provide you with the best quality and the best price for Factory making China Hard Candy Formed Plant Production Line Candy Equipment for Sale, We sincerely welcome friends to negotiate business and start cooperation. We hope to join hands with friends in different industries to create a brilliant future.

We always work as a tangible team to ensure that we can provide you with the best quality and the best price for Candy Equipment for Sale, China Candy Manufacturing Equipment, We have more than 200 staff including experienced managers, creative designers, sophisticated engineers and skilled workers. Through hard work of all employees for the past 20 years own company grew stronger and stronger. We always apply the “client first” principle. We also always fulfill all contracts to the point and therefore enjoy excellent reputation and trust among our customers. You are very welcome to personally visit our company.We hope to start a business partnership on the basis of mutual benefit and successful development . For more information please do no hesitate to contact us..

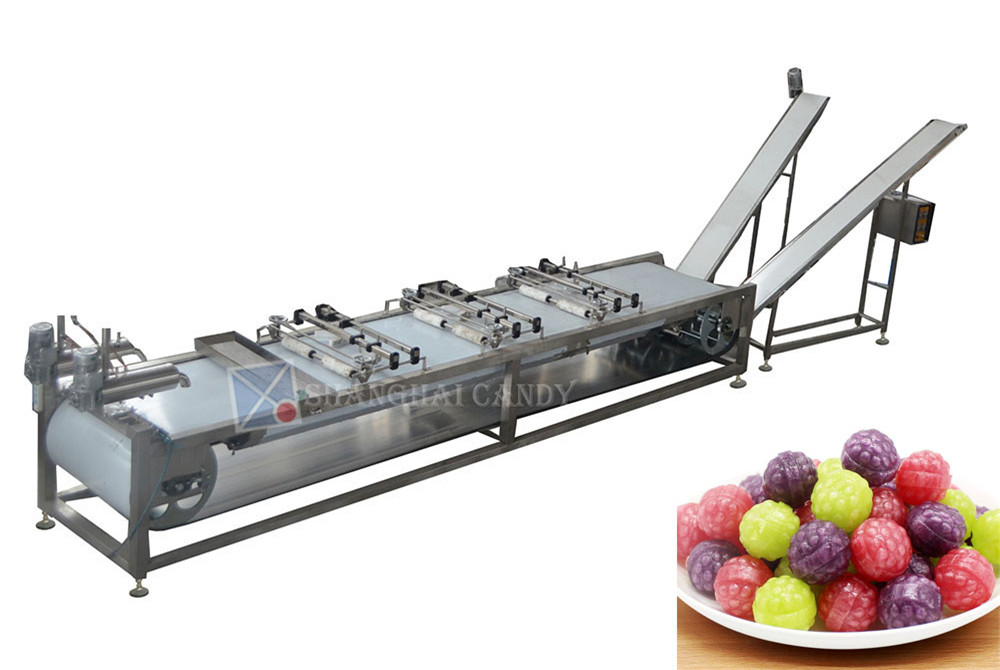

Die forming hard candy line

For production of die formed hard candy, jam center filled hard candy, powder filled hard candy

Production flowchart →

Raw material dissolving→Storage→Vacuum cooking→Add color and flavor→Cooling→Rope forming→Forming→Final product

Step 1

Raw materials are automatic or manually weighed and put into dissolving tank, boil to 110 degrees Celsius.

Step 2

Boiled syrup mass pump into batch vacuum cooker or micro film cooker through vacuum, heat and concentrated to 145 degrees Celsius.

Step 3

Add flavor, color into syrup mass and it flow onto cooling belt.

Step 4

After cooling, syrup mass is transferred into batch roller and rope sizer, meanwhile can add jam or powder inside. After rope getting smaller and smaller, it enter forming mould, candy formed and transferred for cooling.

Die forming hard candy line Advantages

1. Continuously vacuum cooker, guarantee the quality of sugar mass;

2. Suitable for producing jam or powder center-filled hard candies;

3. Different candy shape can be made by changing the moulds;

4. Automatic running steel cooling belt is optional for better cooling effect.

Application

1. Production of hard candy, powder or jam center filled hard candy.

Die forming hard candy line show

Tech Specs

|

Model |

TY400 |

|

Capacity |

300~400kg/h |

|

Candy Weight |

Shell: 8g(Max); Central filling: 2g(Max) |

|

Rated Output Speed |

2000pcs/min |

|

Total Power |

380V/27KW |

|

Steam Requirement |

Steam Pressure:0.5-0.8MPa; Consumption:200kg/h |

|

Working Condition |

Room Temperature: 20~25℃; Humidity:<55% |

|

Total Length |

21m |

|

Gross Weight |

8000kg |

We always work as a tangible team to ensure that we can provide you with the best quality and the best price for Factory making China Hard Candy Formed Plant Production Line Candy Equipment for Sale, We sincerely welcome friends to negotiate business and start cooperation. We hope to join hands with friends in different industries to create a brilliant future.

Factory making China Candy Manufacturing Equipment, Candy Equipment for Sale, We have more than 200 staff including experienced managers, creative designers, sophisticated engineers and skilled workers. Through hard work of all employees for the past 20 years own company grew stronger and stronger. We always apply the “client first” principle. We also always fulfill all contracts to the point and therefore enjoy excellent reputation and trust among our customers. You are very welcome to personally visit our company.We hope to start a business partnership on the basis of mutual benefit and successful development . For more information please do no hesitate to contact us..